Biodiesel Batch No. 30

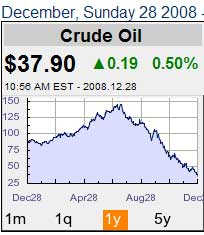

The biofuels landscape has changed quite a bit since I brewed  my first batch of biodiesel in Aug. 2006. Demand for alternative fuels skyrocketed when the price for barrel of crude oil surged to almost $150 this summer. Yet, now the price for crude is back below $40 a barrel, while biodiesel feedstock cost remails high. Unsustainable production methods and a surge in demand for vegetable oils for food have sparked a heated debate over the viability of biofuels. Due to the increased feedstock prices, locally produced biodiesel has been hard to come by, and expensive (over $5).

my first batch of biodiesel in Aug. 2006. Demand for alternative fuels skyrocketed when the price for barrel of crude oil surged to almost $150 this summer. Yet, now the price for crude is back below $40 a barrel, while biodiesel feedstock cost remails high. Unsustainable production methods and a surge in demand for vegetable oils for food have sparked a heated debate over the viability of biofuels. Due to the increased feedstock prices, locally produced biodiesel has been hard to come by, and expensive (over $5).

This weekend I brewed my 30th 200-liter (50 gallons) batch of biodiesel, and so far all the upheaval in the fuel market has mostly passed me by. I don’t intent to gloat – this has the potential to have an impact on me, too. The competition for waste veggie from restaurants has intensified.  The restaurants use less oil and re-use their fryer oil more, due to the high cost. Oil that spent more time in the fryer has a higher percentage of free fatty acids and needs more attention when I turn it into fuel. Despite all this, I still have access to suficient amounts of good quality used vegetable oil at several restaurants in town. The logistics of collecting the oil are fairly easy to manage, because I work in walking distance to most of the places, and I work in collaboration with other biodieselers.

The restaurants use less oil and re-use their fryer oil more, due to the high cost. Oil that spent more time in the fryer has a higher percentage of free fatty acids and needs more attention when I turn it into fuel. Despite all this, I still have access to suficient amounts of good quality used vegetable oil at several restaurants in town. The logistics of collecting the oil are fairly easy to manage, because I work in walking distance to most of the places, and I work in collaboration with other biodieselers.

So now I am up to about 6000 liters (1500 gallons) of homebrew – with no major problems, really. (Knock on wood!) Every batch separated nicely, and I only once had some emulsion issues, which resolved with careful washing and settling. This is not to say I had no challenges – just no major disasters. In fact, batch 30 was a bit of a challenge.

Batch 30 is made of oil from three different places and I usually prefer to make a batch from a single source to keep the quality consistent. With multiple sources you have to blend the oil and titrate many more samples to be confident. So when the first samples for this batch titrated unusually high (3.0) I decided to make new titration solution because the old solution was about 6 months old. And since I had no destilled water handy, I used tap water (local well water). Big mistake. The titrations from this varied between 2 and 4 – on the same sample! Finally I realized that this was not working and went to the store to get destilled water. A new batch of titration solution with destilled water produced much more consistent results (2.2 – 2.5). Lesson learned.

Another interesting lesson I learned earlier this fall. I usually test my fuel using the 3/27 test – or the PHlip test, when I have one. So I was out of PHlip tests, and I tested a fuel sample using the 3/27 test. Within minutes a bunch of glop precipitated – oh shit, I thought. But I was baffled – this batch I had only used really good oil from the Mexican place, which had never caused me any problems. I did another test – same result. So I checked on the web and read up on the 3/27 test. Turns out that the test is temperature sensitive. It had just turned cold, and the temperature in the basement was down to about the mid-fifties (12 Deg. C). When I warmed the methanol and the biodiesel sample to room temperature it worked just fine, and nothing precipitated. BTW – if the temperatures are too warm, this test produces false-negative results.